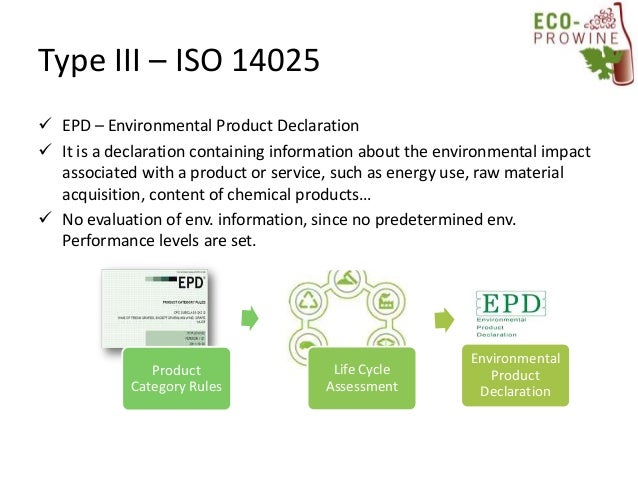

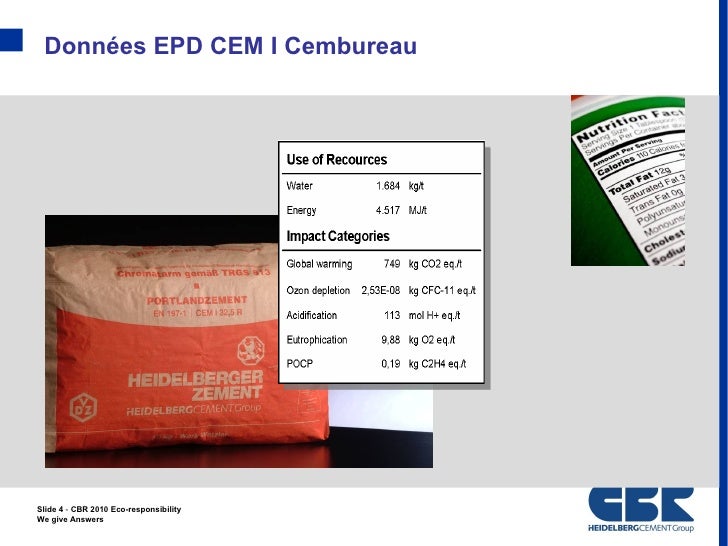

Undefined Sala Lizarraga, Ana Picallo-Perez, in Exergy Analysis and Thermoeconomics of Buildings, 2020 10.4.4 Environmental product declarationĮnvironmental Product Declaration ( EPD) consist of quantified environmental information concerning the cycle of the products (and services) in order to allow a comparison between products that perform the same function. As shown in Section 17.5, fly ash concrete can have significantly lower impacts than average concrete. The concrete industry has developed an industry-wide EPD for concrete and an industry benchmark report for concrete that provides average impacts for a variety of mix designs, which means concrete producers can compare their impacts to these baselines and formulate products that have lower environmental impacts than average. Option 2 (Optimization) awards one point if 50%, by cost, of all products in the building can demonstrate that their products perform better than the industry average or baseline environmental impacts. Concrete producers with EPDs will be able to contribute significantly to this credit because of the wide range of concrete products on most projects. There are no requirements for reducing environmental impacts simply disclosing the product's environmental impacts will support this credit. Under this credit, a plant specific EPD is more desirable (worth the full product), but industry average EPDs (worth half a product) can be used if site specific EPDs are not available. Option 1 (Disclosure) awards one point for using 20 permanently installed products in the building that have published EPDs. Lemay, in Coal Combustion Products (CCP's), 2017 17.4.3 Building product disclosure and optimization-EPDsĮPDs are reports published by product manufacturers that provide third-party-verified information regarding the environmental performance of their product (see Section 17.5). BRE EPD, is published on the GreenBookLive website EPD are valid for 5 years, as dictated by EN 15804 ( CEN (2012b)), and it is the responsibility of the PO to ensure its website is up-to-date, whilst the owner of the EPD ensures that the published EPD is representative of the actual product throughout the validity of the EPD. Following successful verification, the EPD is issued by the programme and published on a public listing service provided by the PO (typically, the PO's website, e.g. The entire process of independent verification assures that the EPD is robust and it is a transparent declaration that is fit for purpose. The verifier determines if the EPD is suitable or not for issue by the programme, and the PO puts in place measures for final approval and the resolution of disputes. The verification process checks the information presented in the EPD and the study as documented in an LCA report for issues including compliance with standards, plausibility and compliance with the programme rules. Some POs have launched online LCA tools to provide access to data and a route to EPD for a much wider audience than has been possible before, for example, BRE LINA The completed LCA study results are then verified by a qualified verifier external to the study (this is the ‘third-party’ verification) usually appointed by the programme. The study is carried out using appropriate software or tools-the PO can provide guidance on the best approach to take. The LCA study can be done either in-house (if the appropriate expertise is available) or externally using a consultant. Some PO, such as IBU, have specific PCR for specific product groups, and others, such as BRE, have one PCR covering all construction products. A valid PCR should be publicly available and published on the PO's website. The programme will either develop a PCR or select an existing PCR (which is an interpretation of EN 15804, CEN (2012b)), developed in accordance with ISO 14025 ( ISO (2006a)) by an expert group including manufacturers and other stakeholders and is peer reviewed, and the entire development process is moderated by a PO. The LCA for deriving the data for the EPD needs to be carried out by an LCA practitioner using appropriate PCR.

EPD programmes are membership based, so the first step in obtaining an EPD is identifying and joining an appropriate programme ( Construction Products Association, 2012). Examples of established PO include BRE (the United Kingdom), IBU (Germany) and AFNOR (France). There are several PO in Europe, typically one in each country or region. Dias, in Performance of Bio-based Building Materials, 2017 9.3.1.5 How to obtain an EPD in EuropeĮPD are verified and issued by EPD schemes or programme operators ( PO).

0 kommentar(er)

0 kommentar(er)